HUBTEX is setting new standards in the safety of operator-guided narrow-aisle industrial trucks with a pioneering development. At FABTECH 2025, the company presented the patented aisle monitoring aid, which was specially designed for use in narrow aisles and protruding loads to enhance collision protection.

The challenge of narrow aisles: minimal distances, limited visibility

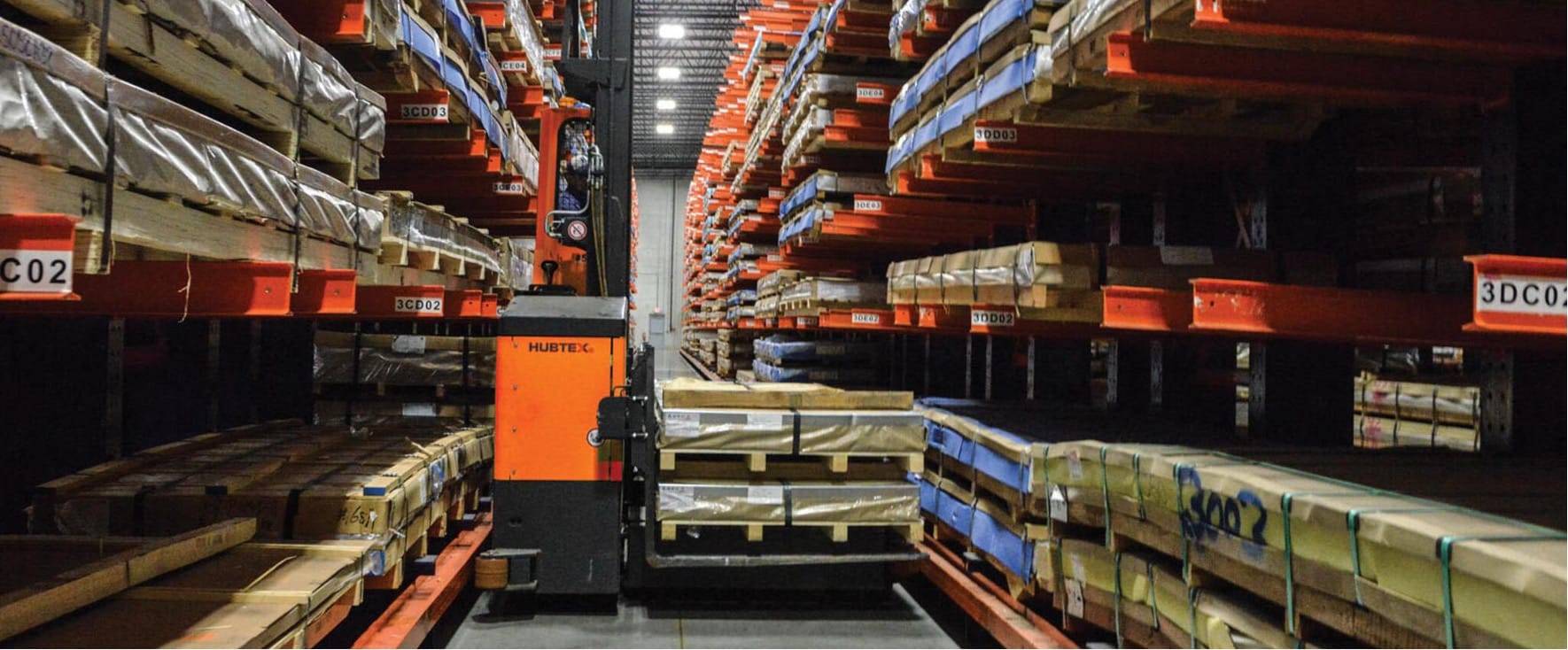

HUBTEX multidirectional sideloaders are often used in narrow-aisle warehouses. In order to make optimum use of the storage capacity, these warehouses are designed in such a way that the vehicles are guided by guidance systems with minimal safety distances – often less than 100mm per side – between the vehicle and the racking system. The forklifts are optimised for use in narrow aisles thanks to a wide range of equipment features, but the operator’s view is severely restricted. At the same time, incorrect positioning can occur when storing long goods, causing long loads in particular to protrude beyond the intended limits into the aisle when stored at an angle. This is a potential source of danger – especially if the multidirectional forklift approaches from the cabin side. Protruding loads are difficult to detect, which can result in collisions with the vehicle chassis, the battery or the cab.

Patented solution: Intelligent environment monitoring with laser sensors

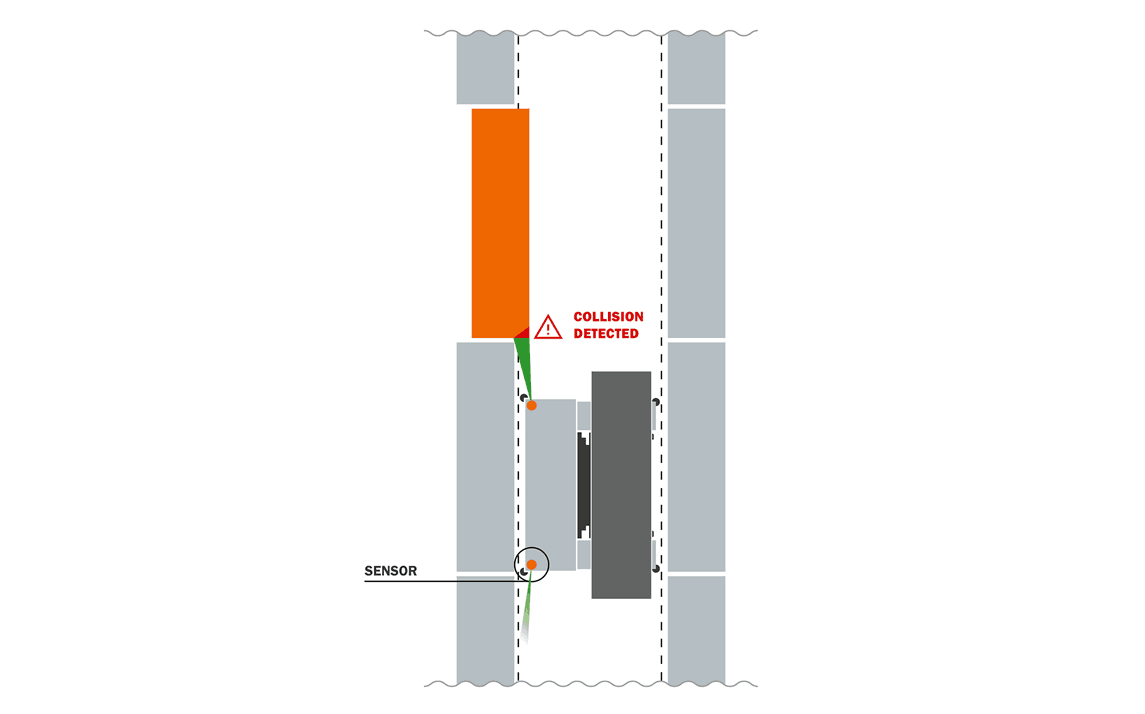

To minimise this risk, HUBTEX has developed an assistance system that monitors the vertical danger zone and automatically initiates countermeasures if necessary. The HUBTEX clear aisle assistant meets this challenge with an innovative, laser-based sensor system that monitors vertical levels in the vehicle environment. Depending on the vehicle configuration, sensors are installed at strategically sensible positions that work both in the main direction of travel and in the opposite direction. In this way, obstacles such as protruding loads are detected at an early stage – regardless of the direction of travel. The sensors work with lidar-based technology and are configured to deliver reliable results even in complex warehouse structures. The monitored area adapts dynamically to vehicle parameters such as speed or lifting height and enables precise, needs-based detection of potential danger zones.

“Our aim was to develop an assistance system that actively supports the driver without placing any additional strain on them,” explains Michael Röbig, Head of Product Management at HUBTEX. “The clear aisle assistant recognises dangerous situations at an early stage and can not only warn the driver if necessary, but also automatically reduce the speed of the vehicle.” With this development, HUBTEX is underlining its innovative strength and commitment to greater safety in warehouse operations.

The new system is now available for the well-known PHOENIX series.

The PhoeniX is an electric multidirectional sideloader designed for handling long, heavy or bulky loads – especially in narrow aisles.

The modular design and flexibility offers more configuration options for load capacity, cabin layout, lift-mast type, tires and more. A key innovation is its electric steering system – designed to save energy compared to traditional hydraulic steering, and much quieter.

Lift Height: Up to 12.5m

Capacity: Up to 35 tons

Adaptable to all applications