Since forming in 1995, HUBTEX Australia has specialised in delivering tailor-made narrow aisle, and long load solutions for materials handling to key industry sectors including logistics, timber, metal and many more.

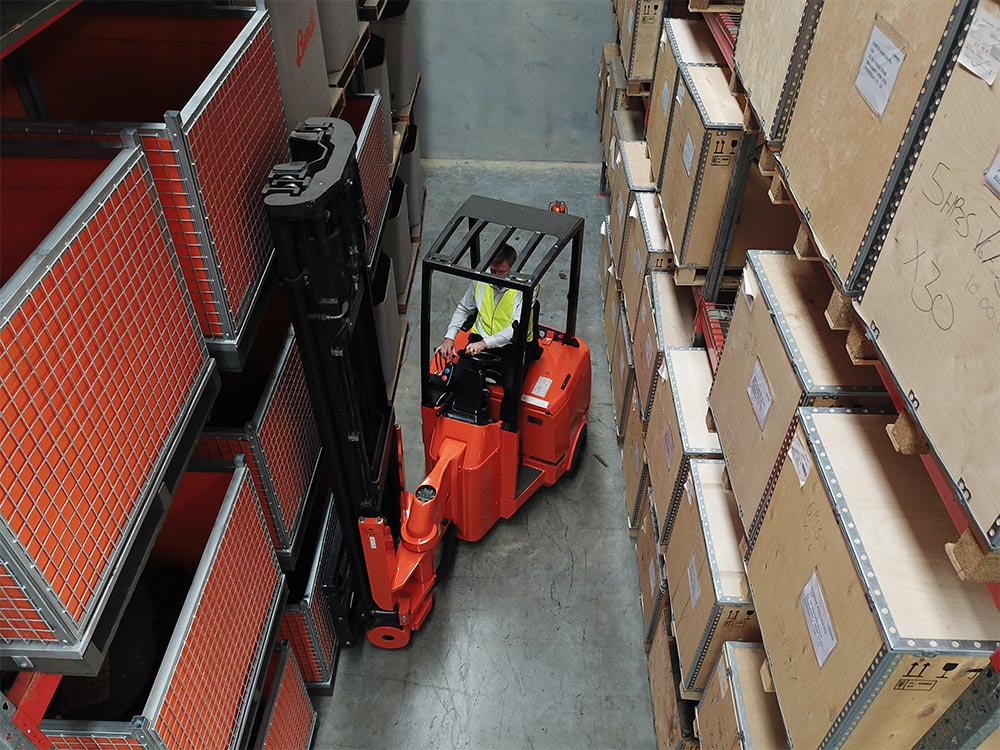

Choose from a comprehensive range of multidirectional sideloaders and articulated forklifts, from the global leading brands of Hubtex, Bendi and Bulmor. They’re designed to handle long loads and standard pallets in the narrowest of aisles. This helps businesses unleash the full potential of their warehouse operations for materials handling.

With the continued rise in property and land costs, companies are being forced to re-evaluate their current approach. They’re looking at innovative ways to maximise the efficiency of warehouse and manufacturing operations. Traditional storage and materials handling processes such as crane systems for transporting long loads and wide aisles suitable for counterbalance forklifts make it difficult to adapt without needing to extend or move premises.

Our many years of experience in a variety of industries have given us an in-depth understanding of the detailed requirements for materials handling solutions in tight spaces. By adopting a narrow aisle philosophy, businesses can make more efficient use of space. They can also increase warehouse capacity by up to 100%, optimise product throughput and save money on expensive new build costs & ancillary equipment.

Understanding narrow aisle solutions for materials handling

In the current climate, many roads lead to smaller warehouse footprints, increased storage density and flexibility to meet specific order requirements. This is where the innovative range of space-saving Bendi articulated forklifts comes in. The versatility of Bendi narrow aisle trucks enables businesses to address the new and evolving challenges in warehouse, 3PL distribution and manufacturing operations today.

In the current climate, many roads lead to smaller warehouse footprints, increased storage density and flexibility to meet specific order requirements. This is where the innovative range of space-saving Bendi articulated forklifts comes in. The versatility of Bendi narrow aisle trucks enables businesses to address the new and evolving challenges in warehouse, 3PL distribution and manufacturing operations today.

How might you ask? To understand this question, one needs to be clear on the materials handling alternatives.

Firstly, the conventional counterbalance forklift is the most widely used type of pallet stacking device the world over. Its original design is practical and cost-effective. The truck does, however, require a lot of space relative to the size of the load, and 4m – 5m aisles are not uncommon.

Work in aisles approximately 3m wide

Reach trucks, on the other hand, are designed compactly with a mast or tines that ‘reach in or out’ from the body of the truck. This allows operators to work in aisles of approximately 3m wide. Due to the compact design, harder tyres are required to overcome stability issues resulting from the high centre of gravity. These smaller, harder tyres dictate that the reach truck is only suitable for inside work or very smooth yards. More often than not, a counterbalance truck is also required to load vehicles from the warehouse.

Whereas, very narrow aisle (VNA) machines, are capable of working in much narrower aisles, approximately 1.7 – 2m wide. This allows them to make the maximum use of storage space. However, these come with many required criteria due to the close tolerances in the aisle. To start with, businesses require expensive super flat floors and rail or wire guidance to enable the truck to be millimetre perfect when travelling in-aisle.

Additionally, VNA trucks require large spaces to move from one aisle to another. This wastes valuable storage space and is a slow process. Finally, VNA machines are only suitable for in-aisle operations, requiring conventional machines to feed the VNA system and take goods away.

A Bendi Articulated Forklift can do it all!

With Bendi trucks, operators can enjoy smooth control thanks to the excellent driver ergonomics. On a regular basis, operators often remark how similar the driving style is when compared to a conventional Counterbalance machine. Featuring the patented ‘Over Rotation System’ which allows the front wheels to rotate 220° degrees, the Bendi offers unmatched aisle performance working in aisles as narrow as 1.8m. This is less than half of what it would take to operate a counterbalance truck. If you were to move from a wide aisle configuration, it could result in an increase of floor space or storage capacity by up to 50%!

A customer of Hubtex Australia moved into a warehouse where the previous company managed to fit 5,000 pallets in the main warehouse. By utilising the Bendi articulated forklift, our client was able to store an impressive 6,000 pallets in less than half of the previous warehouse space!

Property charges, such as heating, lighting and maintenance are also major factors increasing the cost of operating a warehouse or factory. Take a cold store for example, by adopting a narrow aisle solution, businesses can fit more products in the same cubed area. This creates greater storage density, reducing cold storage costs. Something another one of our customers is benefitting from.

Operate both indoors and outdoors!

With a three-area set-up consisting of their standard warehouse, a fridge section and a freezer section, the Bendi articulated trucks work in all three areas negating the need for other material handling equipment. Better still, as the original multi-purpose truck, the Bendi’s also operate both inside and outside meaning double handling is a thing of the past.

Bendi trucks can load and unload trailers on concrete or unpaved yards. Then move straight into the warehouse to place pallets into racking at heights of up to 13m without the need for guidance or expensive ‘super flat floors’. Adding to the flexibility of these Bendi machines, the option of our rear-wheel drive model makes light work of ramps and sloped areas in and around premises.

Offering the versatility and speed of a counterbalance truck, the high lifting capacity of a reach truck and the space-saving of a VNA truck, a Bendi Forklift can truly do it all!

Handle long, bulky and difficult loads?

Our narrow aisle solutions don’t stop with the Bendi. The HUBTEX range of sideloaders, multidirectional forklifts, order picking systems and special-purpose vehicles are designed to maximise the safety and efficiency of long-load operations. Working in a variety of industries such as timber, metal, plastic, building materials and much more, at HUBTEX, we create the unique with the right equipment for every application.

2-in-1 Forklift – FluX Multidirectional Counterbalance Forklift

The new FluX series from HUBTEX is the latest generation of multidirectional counterbalance forklift trucks for indoor and outdoor use. The lift truck with a compact 3-wheel chassis is ideal for handling pallets and long goods in tight spaces.

Thanks to a low-noise, environmentally friendly electric drive combined with an innovative 360° HX steering system for smooth changes in direction from longitudinal to transverse travel, the truck outperforms all other 3-wheel multidirectional trucks when it comes to manoeuvrability, efficiency and user-friendliness

Flexible long load transport in narrow aisles for materials handling

The Hubtex MaxX is a cost-effective, entry-level electric multidirectional forklift. It is designed for indoor or outdoor use, and handling long loads in narrow aisles. As an economical alternative to diesel and gas-powered machines, the MaxX has proven itself to be a serious contender. It has already helped reduce noise and heat pollution at one customer’s site.

Like the FluX, the MaxX features the patented HX steering system allowing operators to change direction without stopping. It has been a real winner at the same site with drivers remarking on the better manoeuvrability in tight areas. They also mention the increase in productivity with not having to stop to change direction.

For anyone looking for diesel or gas-powered options, the Hubtex DQ-X multidirectional forklift is the universal option. It is the undisputed leader among the multidirectional sideloaders when it comes to outdoor use.

Maximum storage and order picking efficiency for materials handling

Our customers have not only increased the storage capacity, but also benefited from an improvement in accessibility and picking efficiency. For many businesses, picking part or bulk orders is a huge part of everyday operations. Therefore the ability to easily access pick faces and select products safely is essential.

One customer went from bulk stacking stillages, to employing a narrow aisle cantilever racking system. The new system was then serviced by a HUBTEX electric sideloader. This not only increased storage capacity, but also had a huge impact on their order-picking efficiency.

In addition to our sideloaders and multidirectional forklifts, we also offer a range of narrow aisle order picking systems. They’re designed to increase productivity and minimise damage. Providing safe, efficient and comfortable picking these machines are ideal for a wide variety of materials. These include large-volume wood-based panels, sheet products, and profiles made of aluminium, steel, plastic, and more.

Are you are considering narrow aisle solutions for the first time or looking for advice on an existing solution? Get in touch with our space-saving experts today on 1300 365 621 or email info@hubtex.com.au.