Greener solutions for timber handling.

ITI’s seamless transition with Hubtex.

Innovative Timber Ideas (ITI) is Australia’s largest independent wholesale timber distributor and is recognised for its innovation, quality, and commitment to environmental stewardship. ITI sought to reduce its carbon footprint by transitioning from LPG-powered machinery to electric multidirectional forklifts as part of its sustainability efforts. This shift was made possible through a strategic partnership with Hubtex Australia.

Current Fleet

ITI relied on LPG-powered trucks across its sites in Sydney. However, these trucks became increasingly inefficient. The move to electric trucks undoubtedly offers a cleaner, quieter, environmentally friendly and improved efficiency option.

Optimisation

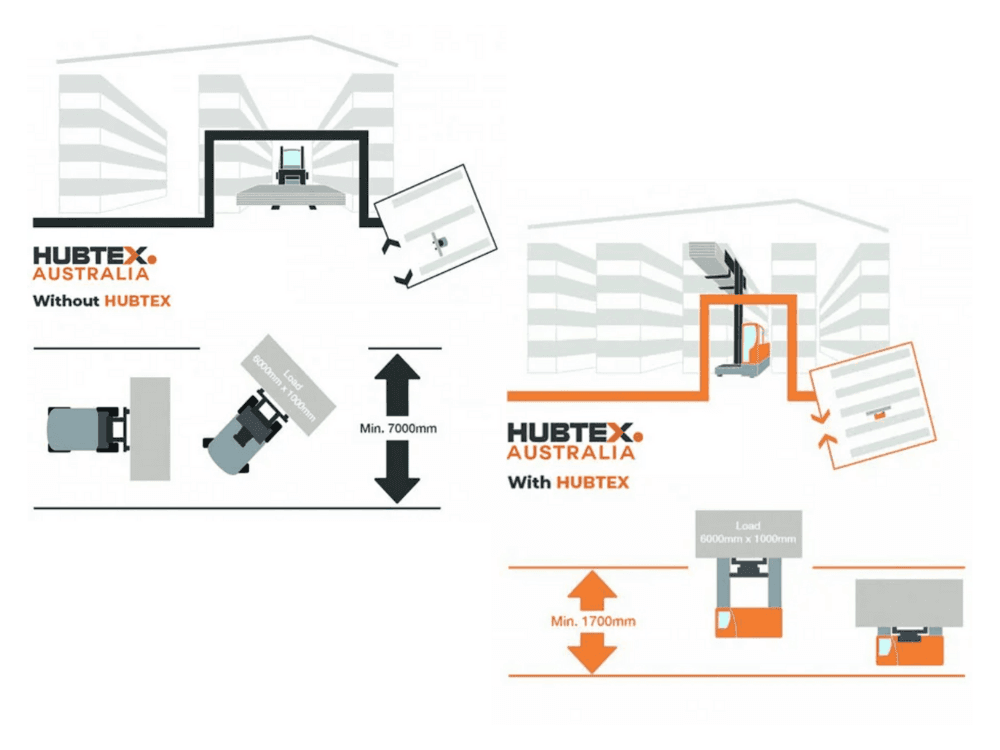

A comprehensive evaluation of ITI’s requirements was conducted, which identified an opportunity to optimise warehouse space by reducing the existing aisle widths. Lithium-ion batteries were also introduced to allay charging concerns.

Demonstration

ITI visited our Riverstone depot to see demonstrations of the MaxX and FluX multidirectional sideloaders. In addition to seeing the machines in action, they met the Hubtex Service Team and observed the extensive parts inventory and customer support services.

The benefits.

Increased Storage Space

Hubtex machines’ compact size enabled the reduction of aisle width, increasing storage capacity.

Environmentally Friendly

Hubtex Trucks are a safer and cleaner alternative to LPG trucks.

Patented HX Multidirectional Steering System

HX Steering eliminates the need to stop when changing directions.

All machines were ordered and supplied from stock.

As a leading global manufacturer, Hubtex Australia holds a wide range of stock machines. From here, the first three machines were delivered – two MaxX45 multidirectional sideloaders and a FluX40 multidirectional forklift, all fitted with state-of-the-art lithium-ion batteries.

After introducing three Hubtex machines, James Bailie, Branch Manager of ITI, commented,

Our Comments

“

We initially had reservations about transitioning to electric Hubtex machines, but after witnessing their performance, it’s clear they offer a superior solution for the business. Our drivers noted the improved manoeuvrability in tight spaces and appreciated the seamless, uninterrupted operation without the need to stop and change directions.

Convinced that they had made the right decision, and with a need to replace unreliable equipment, a third Hubtex MaxX45 was ordered, and delivered, from stock, within two weeks! The compact design, and HX multidirectional steering of the Maxx45 led to increased storage capacity and more efficient product handling.

The complete solution

Responsible for transporting stock between ITI’s two sites, the FluX 40 multidirectional counterbalance forklift proved instrumental due to the two locations being situated on different levels. The FluX combines the functions of a traditional forklift and a sideloader in one vehicle. Featuring the patented HX steering system, the FluX can switch between lengthwise and crosswise travel without stopping, reducing tyre wear and maximising the efficiency of handling operations.

The introduction of lithium-ion battery technology addressed ITI’s charging concerns by allowing faster ‘opportunity charging’, ensuring seamless operations across shifts. Other key benefits including zero emissions, zero maintenance needs, and a better working environment for operators due to reduced noise and fumes.

In conclusion, the collaborative approach between ITI and Hubtex Australia exemplifies how tailored solutions and exceptional service can drive long-term success. By embracing Hubtex innovative solutions, ITI has enhanced operational efficiency and reinforced its commitment to sustainability and innovation—principles that have defined its business for over 33 years.

The two-in-one lift truck!

Transports long loads and standard pallets, combining the benefits of a forklift and a sideloader in one machine.

We Know the Best Solution…

We know that handling heavy loads in a confined space presents users with special challenges. Arrange a free consultation with our specialists to get the best possible solution for your application, contact us now.