No matter the size, warehouses are expensive for companies to operate. When you break expenses down and look at the building, energy costs, machinery and labour it all adds up to a significant amount of money which is why it is crucial to manage your warehouse space efficiently.

There are several ways companies can manage their warehouse space more efficiently, some of which include simplifying their goods handling processes, maximising the utilisation of storage space and using the optimum materials handling equipment.

Maximise Space Utilisation

When you think about it heating, lighting and maintenance all play their part in the increasing cost of operating a warehouse, alongside the costs of the building itself and staffing it. Bearing this mind, any unused or misused space could potentially be costing you a considerable amount of time and money.

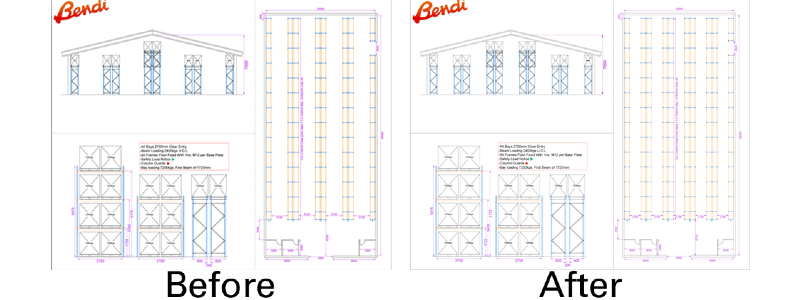

Regular re-evaluations of the design and layout of your warehouse is essential as it will give you a clear picture of ways to improve efficiency along with increasing the amount of goods stored to allow for company growth and expansion without the need to extend or move premises. By maximising the space available in your warehouse, you will be able to extend the life of existing facilities along with reducing any offsite storage by bringing everything under one roof.

Materials Handling Equipment

The use of Articulated Narrow Aisle Forklifts can significantly reduce the amount of aisle space required for placing and retrieving loads from the racking. Operating in aisles as narrow as 1.8m and lifting up to a height of 13.5m, articulated forklifts have the versatility and speed of a counterbalance truck, the high lifting capacity of a high reach truck and the space saving of a narrow aisle truck, all in one.

The innovative design of articulated narrow aisle forklifts allows the operator to rotate the mast 220 degrees whilst the main body of the truck stays stationary. The main benefit of this revolutionary design means warehouse racking doesn’t need to be as spaced out to accommodate the likes of a counterbalance or high reach truck. Instead the racking aisles can be as narrow as 1.8m allowing for more racking and extra storage space.

Simplify Goods Handling

Could you simplify your goods handling process? Every time you pick up a load, it costs time and money for your company. By reducing the amount of touches when handling loads, you could reduce costs. Not to mention the fact that you may be able to consolidate your forklift fleet. Do you have any trucks that are idle for considerable lengths of time?

With an Articulated Narrow Aisle Forklift, one truck can do it all. Working both inside and outside, a Narrow Aisle Forklift does not need expensive super flat floors or wire guided aisles to work. The versatility of Articulated Forklifts allows the operator to load and unload lorries as well as replenish the racks, all in one, therefore reducing the amount of touches per load.

Can you manage your warehouse space more efficiently? Our national team of space saving experts are on hand to offer advice on racking and warehouse storage systems specific to your requirements. We offer a comprehensive range of Articulated Narrow Aisle Forklifts from Bendi, the world’s most popular Articulated Forklift Truck. Watch our introduction video here to see just how versatile the Bendi trucks are.

If you are looking for advice on warehouse design and layout or more information on our range of Bendi Articulated Forklifts get in touch on 1300 365 621.